01.07.2014

ALADDIN'S CAVE

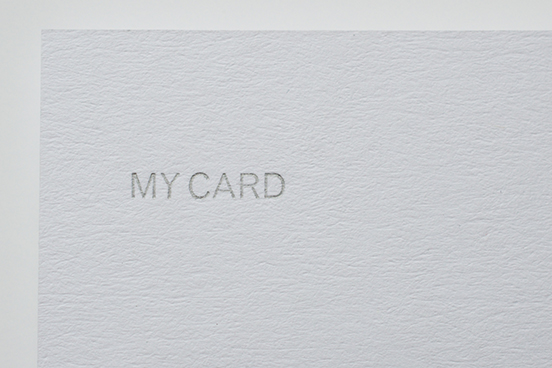

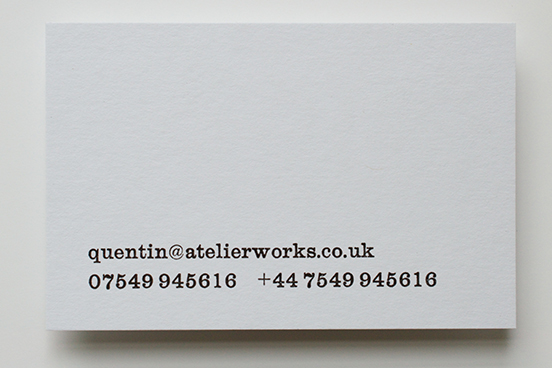

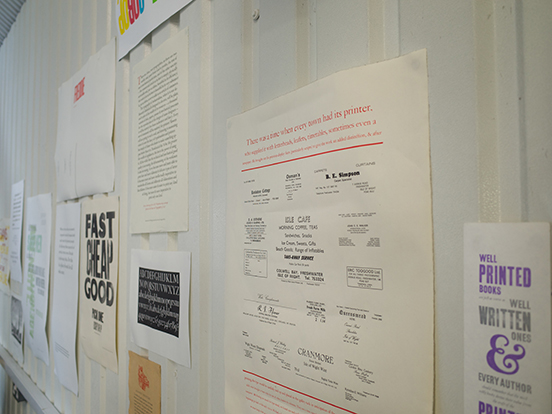

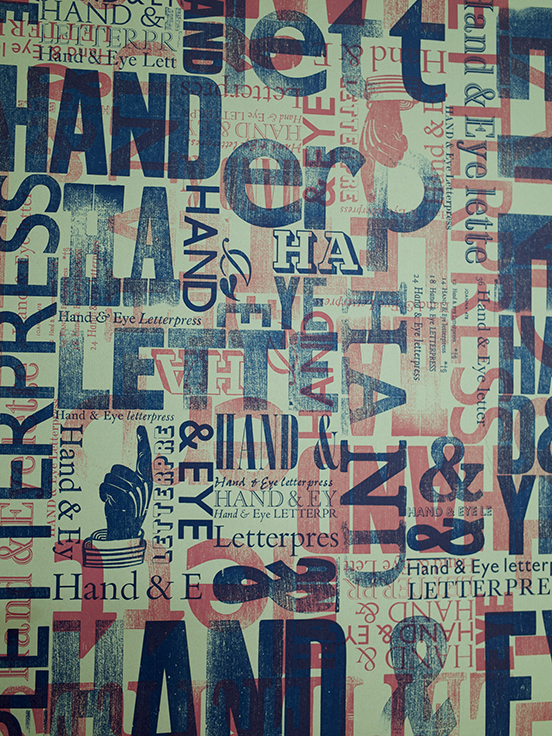

Popped round to pick our new cards from Phil Abel, master printer at Hand & Eye. His railway arch workshop is a Wonderland of objects bound to thrill any designer. Towers of ink pots, sets of type trays, type casters, partially printed sheets, wood type, just writing this list my chest is hammering and I am becoming breathless.

The great fact that makes all this super-exciting is that this is not a museum, Phil is a jobbing printer, working day-in, day-out producing real work with this equipment, even the casters function. Let me be clear about what I mean by the word "jobbing". I mean that each task that you undertake is a job, brought to you by a client. John McConnell, partner of Pentagram, wrote a piece in "Living by Design" (Whitney Library of Design 1978), in which he described that making the most of each client's job a dignified, indeed noble way of practicing design. The struggle for anyone working for clients, McConnell suggests is "how to reconcile their concept of aesthetic quality with commercial pressures". He cited Josef Müller-Brockmann as a jobbing designer who had brought magic to each project. Phil, in his railway atelier, does the same.

To be a letterpress printer in this day and age is a double or even treble achievement. First: its hard to be a small-scale printer, focused on quality. Second: there are time, quantity and design constraints which you have to allow for in this form of printing. Thirdly: Phil is working with equipment that is no longer "supported" as the manufacturers say. He has to fix it himself. The Monotype caster has been jerry-rigged to run off a MacBook in the most ingenious way, breathing fresh modern life into these old machines.

You can see lovely films of Phil's equipment in action (!): the Monotype Supercaster here, and Heidelberg cylinder press here.

Quentin Newark

feeling old

Phil in inky apron, chats with John Powner.

Phil in inky apron, chats with John Powner.

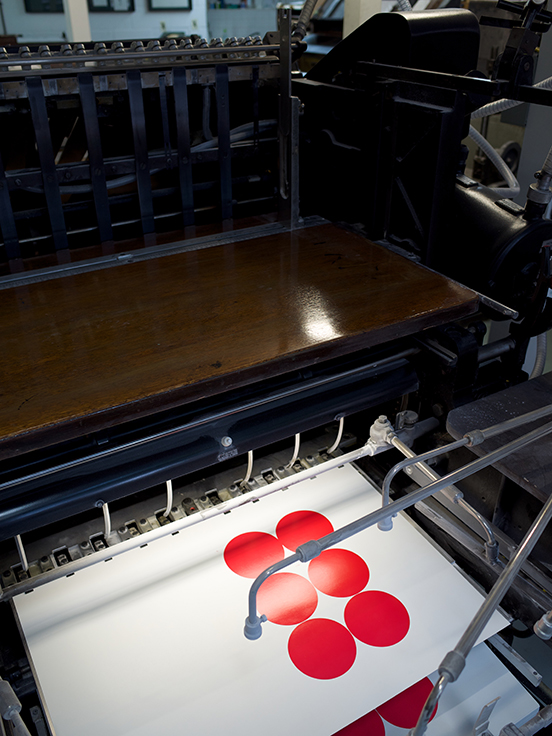

Heidelberg Cylinder Press, with grippers like long metal fingers, handling the sheets of card.

Heidelberg Cylinder Press, with grippers like long metal fingers, handling the sheets of card.

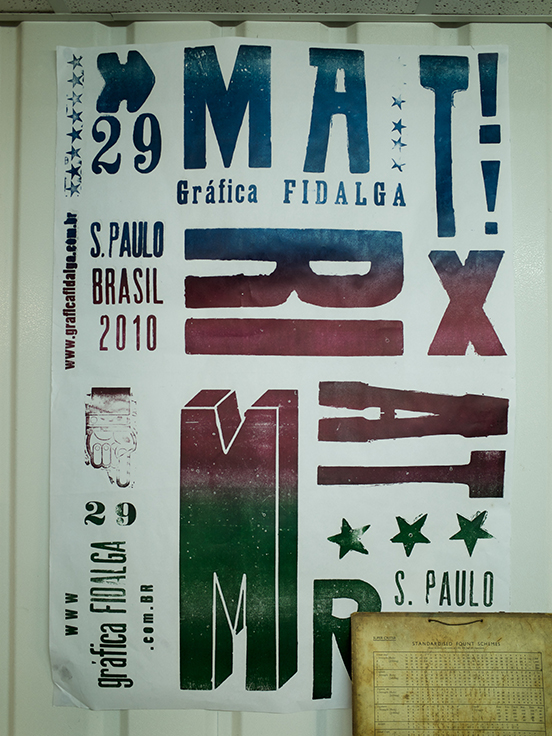

Display fonts. The Supercaster only goes up to 14 point, anything above has to be set by hand. This looks like Gill.

Display fonts. The Supercaster only goes up to 14 point, anything above has to be set by hand. This looks like Gill.

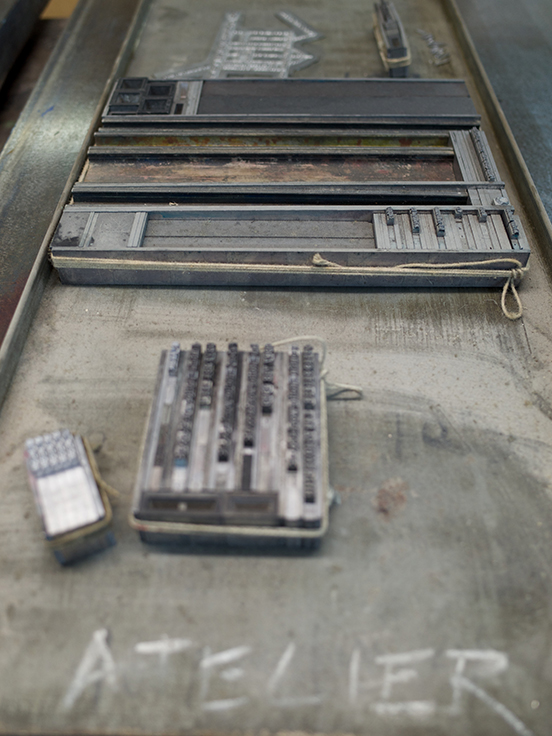

Phil's collection of galleys, the strips of set type bound in a form. Some of this type has lain here for twenty years (that is when Phil printed our first letterhead).

Phil's collection of galleys, the strips of set type bound in a form. Some of this type has lain here for twenty years (that is when Phil printed our first letterhead).

Dissed type, ready to be returned to the melting pot. Amongst American typesetters, this is known as the Hellbox.

Dissed type, ready to be returned to the melting pot. Amongst American typesetters, this is known as the Hellbox.

On the right is the composing stone, where type is assembled, ensuring it is level.

On the right is the composing stone, where type is assembled, ensuring it is level.

Phil's MacBook Air joined ingeniously to the Monotype Supercaster. Which means he can set type automatically from modern text documents.

Phil's MacBook Air joined ingeniously to the Monotype Supercaster. Which means he can set type automatically from modern text documents.

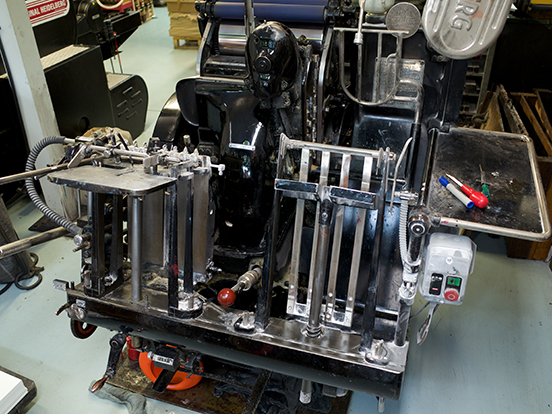

This exotic collection of tubes, like early Dr Who equipment, translates the binary code of the digital letterforms from Phil's MacBook into pnuematic pulses (puff of air down those transparent tubes) that drive the Monotype Supercaster. It looks crude, but is a perfect example of the kind of innovation needed to keep machinery developed in the 1920s functional nearly a hundred years later. Like Erik Spiekermann says in the film promoting his new printing workshop, "these machines never break". They don't break, but innovation is needed to keep them relevant.

This exotic collection of tubes, like early Dr Who equipment, translates the binary code of the digital letterforms from Phil's MacBook into pnuematic pulses (puff of air down those transparent tubes) that drive the Monotype Supercaster. It looks crude, but is a perfect example of the kind of innovation needed to keep machinery developed in the 1920s functional nearly a hundred years later. Like Erik Spiekermann says in the film promoting his new printing workshop, "these machines never break". They don't break, but innovation is needed to keep them relevant.

The Monotype Supercaster, with overalls artfully draped on it.

The Monotype Supercaster, with overalls artfully draped on it.

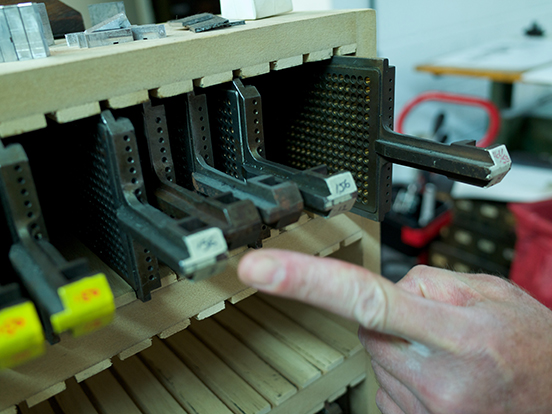

Phil pointing at a display matrix, the matrix determines what font the Supercaster casts.

Phil pointing at a display matrix, the matrix determines what font the Supercaster casts.

Boxes from the Monotype Display Matrix Lending Library. A service that has been running since 1913. The hire is 15/- (fifteen shillings) a week, 75p.

Boxes from the Monotype Display Matrix Lending Library. A service that has been running since 1913. The hire is 15/- (fifteen shillings) a week, 75p.

Close up of the Supercaster. Watch this brief film to see it functioning.

Close up of the Supercaster. Watch this brief film to see it functioning.

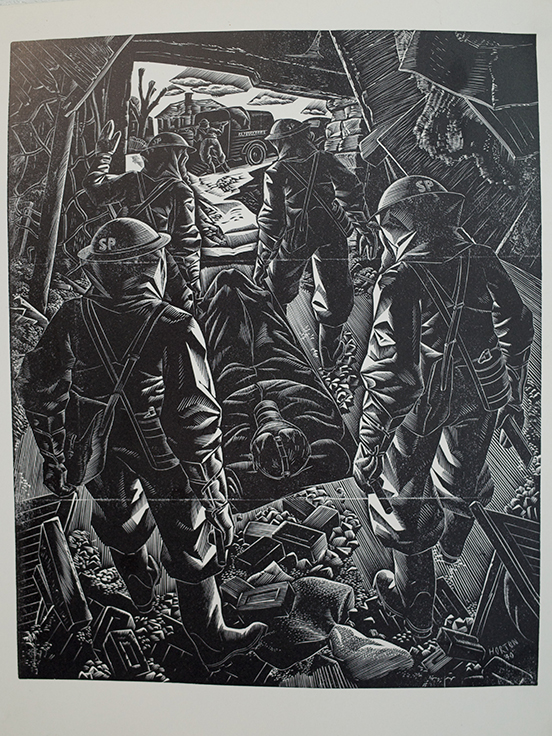

Phil has proofed up some woodcuts he inherited, including this beautiful image of a stretcher party (SP on their helmets) bringing an injured civilian, wearing a gas mask, out of a house after German bombing. The lines are fine as hairs. Both skill and bravery that belong to another era.

Phil has proofed up some woodcuts he inherited, including this beautiful image of a stretcher party (SP on their helmets) bringing an injured civilian, wearing a gas mask, out of a house after German bombing. The lines are fine as hairs. Both skill and bravery that belong to another era.